Straight, Forward, Sealing.

Case Sealers

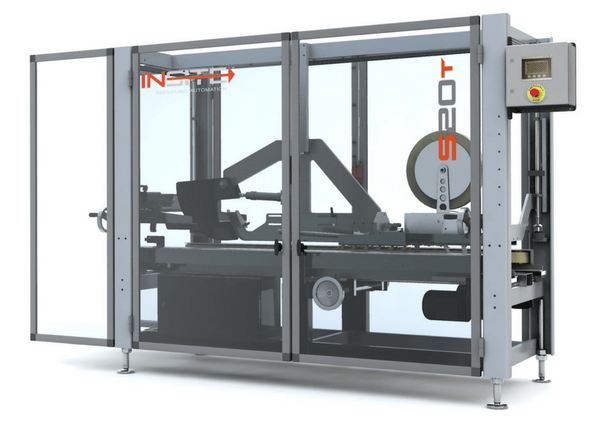

INSITE Packaging Automation’s case sealers boast a clean, minimalist design, despite being packed with numerous functions and features that simply make the case sealing process better for our customers. These features come standard, not as upgrades that you might find with competing sealers. Our case sealer machines handle a large range of case sizes while accommodating enormous variations in the number of cases that can be sealed per minute.

Our case sealers — also referred to as carton sealers and box sealers — are safe, dependable, efficient to operate and effortless to maintain. Let’s explore all the many ways INSITE’s case sealers can improve your business’ packaging operations while saving you money and time.

Key Features of INSITE’s Case Sealers

A sealed case is only part of the story. How you get to a sealed case is just as important. Does your case sealing equipment seal your cases fully and dependably? Does it run reliably without jamming or breaking down? Does it handle the cases firmly enough to control them, but not so firmly that it damages your product? Does it keep your operators safe and run so smoothly and efficiently that it allows those operators to spend time adding value in other parts of your operation? These are questions that an experienced case sealer manufacturer can help you answer. And with INSITE’s thoughtfully designed case sealers, the answer to all those questions is a resounding "yes." A sealed case is only part of the story when it comes to case sealers. How you get to a sealed case is just as important. Ask yourself, does your case sealing equipment:

- Seal your cases fully and dependably?

- Run reliably without jamming or breaking down?

- Handle the cases firmly enough to control them but not so firmly that it damages your product?

- Keep your operators safe?

- Run so smoothly and efficiently that it allows your operators to spend time adding value in other parts of your operation?

These are questions an experienced case sealer machine manufacturer (occasionally referred to as ‘carton sealer machine manufacturers’) can help you answer. With INSITE’s thoughtfully designed top seal packaging machines—the ultimate modern packaging system—the answer to all these questions is a resounding "Yes."

Spring-loaded side belts

Case sealers need to hold and convey cases without damaging them. INSITE’s case sealing machine uses spring-loaded side belts to get just the right amount of grip. This side belt configuration also allows for a range of case width variances throughout a given production run.

Standard touch-screen controls

Modern packaging equipment should live up to modern usability standards. At INSITE, we believe even base-level case sealers should be “smart” and deliver on high expectations for intuitive system controls. Our case sealers put this control right at the tip of your fingers.

Full-length guard doors

Full-length guard doors with safety switches on our cardboard box sealers provide exceptional operator safety while allowing for full access when the machine is stopped. When your operators run the case sealer machine, guard doors keep them safe. But when they replenish tape or perform preventative maintenance, there’s nothing to get in their way.

Tilt-accessible tape head

Even the tape sealer shows INSITE Packaging Automation’s thoughtful design. Our case sealers’ tape heads tilt easily for superior access or removal. You can replace the existing roll or perform a quick swap of the entire tape head. Either way, this critical piece of case sealing equipment won’t slow down your team.

Major flap control

Any good case sealer needs a mechanism to control a case’s major flaps. That’s because any good packing sealing machine manufacturer knows that major flaps are a primary cause of jammed or damaged cases. At INSITE Packaging Automation, we wholeheartedly agree. What we don’t agree with is charging our customers extra money to get something so essential to the case sealing process. Our major flap control feature comes standard with our reasonably priced case sealers, which some of you may refer to as “automatic box sealers” or “automatic box tapers.”

Portability and dexterity

If your operation needs a standalone high-speed case sealer to be in different places at different times, that’s no problem. INSITE’s case sealers have a caster option that allows easy relocation to different lines as plant demand or design changes dictate. If these changes require a different orientation for your automatic carton sealer machine, this poses no problem. Our case sealers easily convert between left- and right-hand operation.

Bottom tape option

Optional addition of bottom tape seal.

Case Sealer Options

Discover a comprehensive list of INSITE’s case sealer options below. Choose the options that fit your business need.

| Option | Description | Included in base price |

|---|---|---|

| Left-Hand or Right-Hand Orientation | Choose from either left hand or right hand orientation for any machine | ✔ |

| Touch Screen Controls | Touch screen HMI with capacity to store up to 29 recipes | ✔ |

| Major Flap Control | Major flaps are trapped open while forming minor flaps, which improves uptime | ✔ |

| Caster Portability | Locking casters are available for ease of mobility | |

| Low Tape, Low Magazine with Stack Light | Provides audio/visual feedback and low material sensing | |

| Spare Parts Kit (Tape) | General wear and critical spares kit for tape sealers | |

| Spare Parts Kit (Glue) | General wear and critical spares kit for glue sealers | |

| 3" Dekka Top Tape | Replaces standard 2" tape head to enable wider adhesion | |

| 2" Bottom Tape | Tape head for bottom sealing when hand packing or in addition to glued flaps | |

| 3" Dekka Bottom Tape | Replaces standard 2" tape head to enable wider adhesion | |

| 2" INSITE Tape Head (for Glue) | Spare tape head for quick replacement or staging tape rolls externally from the machine | |

| RH Electrical Cabinet (Replaces Standard LH cabinet) | Relocates the electrical cabinet for maintenance convenience or ease of access | |

| Polycarbonate Dust Cover | Reduces dust and debris within the machine working area | |

| Infeed Metering Gate | Meters the cases into the sealer | |

| Quick Access Overhead | Enables quick release of the overhead case hold-down assembly and easy lifts to quickly clear a jam | |

| Open Flap Detection | Sensors that detect open or unsealed top flaps |

Case Sealer Specifications

Below, you’ll discover a comprehensive list of INSITE Packaging Automation’s case sealer specifications. If you need additional information, contact us. We’ll provide all the resources you need to choose the carton sealer your business demands. REACH OUT TO US

| S20G | S20T | S30G | S30T | |||||

|---|---|---|---|---|---|---|---|---|

| Max. Speed (cpm) | 20 | 20 | up to 30 | up to 30 | ||||

| Min. Case Size | 8" (L) x 5" (W) x 4" (D) Combined minimum case size. Smaller length or width sizes optional. Contact us for details. | |||||||

| Max. Case Size | 22" (L) x 17" (W) x 18" (D) Combined maximum case size. Larger length or width sizes optional. Contact us for details. | |||||||

| Min. Flap Length | 2.50" | |||||||

| Max. Flap Length | 8" | |||||||

| Case Types | Regular Slotted Container (RSC) or Half-Slotted Containers (HSC) | |||||||

| Infeed / Discharge Height | 22" to 32" | |||||||

| Machine Footprint | 6.9' x 2.7' | |||||||

| Frame to Floor Clearance | 5" to 14" (adjustable) | |||||||

| Frame | Plate steel | |||||||

| Cleaning - Structure | All-purpose, spray-on cleaner, 5-10 pH (non-electrical only) | |||||||

| Finish | Powder coat | |||||||

| Environment | Machine is intended to operate in dry, non-wash down, low-humidity environments | |||||||

| Max. Ambient Temp. | 100° F | |||||||

| Min. Ambient Temp. | 35° F | |||||||

| Max. Humidty | 75% | |||||||

| Changeover Points | 8 | |||||||

| Changeover Types | HMI input, hand wheel, hand lever/clamp | |||||||

| Changeover Time (approx) | ~2 to 4 minutes (total) | |||||||

| Top Tape Width | N/A | 2" or 3" | N/A | 2" or 3" | ||||

| Glue System | Nordson ProBlue 4 | N/A | Nordson ProBlue 4 | N/A | ||||

| Vacuum System | Venturi-style | |||||||

| Guarding | Lexan doors with electronic switches | |||||||

| Cleaning - Lexan | Clean with a soft, damp cloth. Abrasive pads should not be used. | |||||||

| Lubrication | Non-food grade, lifetime lubrication | |||||||

| NEMA Rating | 12 | |||||||

| Electrical Components | Allen Bradley, Powerflex VFDs | |||||||

| Power Requirements | 480 3Ø / 60 HZ | |||||||

| Electrical Drops | 2 | 1 | 2 | 1 | ||||

| Main Electrical Drop | 30 AMP rated disconnect; fused for 15 AMP | |||||||

| Glue Electrical Drop | 30 AMP; fused @ 15 AMP | N/A | 30 AMP; fused @ 15 AMP | N/A | ||||

| Est. AMP Loads | 6.7 | 1.7 | 6.7 | 1.7 | ||||

| Air | 4.25 SCFM @ 70 psi | 3.5 SCFM @ 70 psi | 4.25 SCFM @ 70 psi | 3.5 SCFM @ 70 psi | ||||

| Machine Efficiency | Case and/or product samples are required to validate size range and guarantee speed rates. | |||||||

| Options | Low Tape Alert (with stack light); Caster Portability; spare parts | |||||||

Case Sealer Innovations

INSITE Packaging Automation is committed to serving your business through peerless packaging solutions that optimize production efficiency and give you the biggest return on your investment. A mission of ours is to continuously build on new ideas that make our packaging equipment even more effective. INSITE case sealers use a range of inventive technologies, systems and designs to increase the speed, quality and reliability of your sealing operations, all while respecting your budget. Explore below for a rundown on a few of these innovations.

-

Flap containment

Most sealers require major flaps to have full clearance from minor flaps. In these case sealing machines, a case variance can easily miss that clearance and cause damaged flap corners. Like INSITE Packaging Automation’s case sealers, other high-end packaging systems on the market contain major flaps effectively and consistently. Unlike our modern packaging system, however, these machines can often be expensive and cost-prohibitive for CPG producers.

-

Single machine with vast functionality

With INSITE’s case sealers—sometimes inaccurately referred to as carton sealers—you can cover a wide range of operating requirements. Our automatic box sealers have the ability to handle a large swath of case sizes while running anywhere from 1 case per minute to 30 cases per minute. With INSITE Packaging Automation, you get the best of both worlds: less machine and more capability.

-

Designed to save

INSITE's case sealing machines have been thoughtfully designed to limit costs during the machine sourcing and building processes, including reducing packaging weight and size. One machine covering a wide range of case sizes and speeds allows for economy of scale. Similarly, machine symmetry and a carefully designed sealing module enable our parts to be consistent regardless of machine orientation or configuration. So whether you want a left- or right-hand machine or glue or tape seal, these configuration changes have no negative impact on our cost structure. The result? A high-end case sealer at a not-so-high-end price.

Innovation With Intent

INSITE Packaging Automation machines and technologies exist to increase the value and quality of your company’s packaging systems. All ideas and innovations we develop serve this singular purpose. As your production requirements and aspirations change, your automated packaging solutions need to keep up. Through tireless innovation, INSITE will help you meet and surpass your packaging goals—no matter how challenging or ambitious they become.

INSITE combines leading-edge automation technology with unrivaled customer service, empowering your business with the tools it needs to take your packaging automation to the next level. LET'S CHAT

Case Sealer Resources

Are you looking for more detailed information on automatic case sealers and how they operate in a real-life production environment? If so, then you’ve come to the right place. INSITE Packaging Automation is proud to offer the resources you require to better understand and capitalize on the latest case sealing machine options.

Case Sealer Floor Plan Specifications

Customers needing precise information about INSITE Packaging Automation’s case sealers, (which are sometimes mistakenly referred to as carton sealers) benefit from our collection of case sealer floor plan PDFs and DWGs. Our packaging machine design PDF diagrams can give your team a good sense of how our case sealers will occupy space on your facility’s floor.

-

Floor Plan for Sealer / Glue.pdf

This 1-page pdf provides you with a clear understanding of the space that our glue case sealer will occupy on your plant floor.

-

Floor Plan for Sealer / Glue.dwg

This dwg file provides you with a clear understanding of the space that our glue case sealer will occupy on your plant floor.

-

Floor Plan for Sealer / Tape.pdf

This 1-page pdf provides you with a clear understanding of the space that our tape case sealer will occupy on your plant floor.

-

Floor Plan for Sealer / Tape.dwg

This .dwg file provides you with a clear understanding of the space that our tape case sealer will occupy on your plant floor.

-

Definition: Left Hand Machine.pdf

While this pdf describing a 'left hand' machine uses an erector to demonstrate, the 'hand' of the machine is still determined the same way.

-

Definition: Right Hand Machine.pdf

While this pdf describing a 'right hand' machine uses an erector to demonstrate, the 'hand' of the machine is still determined the same way.

Case Sealer Videos

Customers wanting to see these modern packaging machines in action can gain perspective by watching INSITE’s case sealer videos. Although these videos should adequately highlight our case sealers’ tape sealing capabilities, if they leave you wanting more, please don’t hesitate to contact INSITE directly.

-

Case Sealer 3D Video

Explore the innovations, features and specs of our Case Sealer.

-

S20T Tape Seal Animation

Check out this animation depicting our S20T tape top sealing machine as it accepts incoming product, controls the major flaps and seals the case tops!

Discover INSITE’s Case Erectors

If you’re looking for the best case erector machine, INSITE Packaging Automation’s solutions are bound to delight your team.

Just as with INSITE’s case sealers, our case erectors are safe to use, dependable, efficient to operate and simple to maintain. Our case erectors can work in tandem with our case sealers to help businesses level up their packaging operations.

Our case erectors can make light work out of converting case blanks into fully erected, bottom-sealed cases reliably and with lightning speed.

FAQ: Case Sealers

-

What is a case sealer?

A case sealer is a kind of equipment used for closing or sealing corrugated boxes. These highly efficient machines, available in semi-automated and fully automated types, expedite the case sealing process. With fully automatic case sealers—offered by INSITE Packaging Automation—operators are not required to participate in the case sealing process, as all functions can be completely automated.

Case sealers are known by many names such as case sealing machines, case sealing systems, case sealing conveyors, case sealing equipment and automatic case sealer machines. These machines are also called carton sealers, carton sealing machines, carton box sealers, carton sealing equipment, carton sealing tape machines, carton top sealers, automatic carton sealers, automatic carton sealer machines and automatic carton sealing machines.

Still others refer to this type of equipment as cardboard box sealers, cardboard box sealing machines, box sealers, box sealer machines and box sealing machines. Furthermore, many refer to case sealers by other names such as packing sealing machines, packing sealers, packaging sealer machines, sealer packaging machines, sealing machines for packaging, top seal packaging machines, tape sealing machines and tape case sealers. Finally, case sealers are also sometimes called packaging solutions, packaging equipment and packaging machinery.

It’s clear that case sealers have earned a lot of names over the years. If your business is searching for the best case sealer, we at INSITE Packaging Automation believe you’ll find exceptional value and extraordinary design in our high-speed case sealers.

-

Are INSITE’s case sealers fully automatic case sealers?

Yes, INSITE’s case sealers qualify as fully automatic case sealers. Additionally, because of the speed ranges they’re capable of, our auto case erectors may be referred to as high-speed case sealers.

-

How do I determine “machine hand”?

INSITE determines machine hand by standing on the operator, or HMI, side of the machine and observing the direction cases travel. If a case blank moves from right to left as it’s erected and sealed, you are looking at a left-hand machine. If the case blank moves from left to right as it’s erected and sealed, you are looking at a right-hand machine. (See diagram.)

-

Does 'case hand' matter with INSITE’s case sealers?

No. INSITE’s fully automatic carton sealing machines can run left- and right-hand cases.

-

What type of hot-melt glue does INSITE recommend?

INSITE Packaging Automation recommends HB Fuller Advantra PHC 9256.

-

How do I configure a case sealer, and what options are available?

Our Get a Quote page will walk you through the fast and easy configuration process.

-

What is the cost of a sealing machine from INSITE?

Go to our Get a Quote page to learn the case sealing machine price for INSITE Packaging Automation’s two models of case sealers. (Note that this machine type is also sometimes mistakenly referred to as a carton sealing machine, so, although you may search for a carton sealing machine price, what you may really need is a case sealing machine price.) This page will walk you through the configuration process and provide you a box sealing machine price for your configuration. Our carton sealing machine prices are tailored according to your configuration specifications.

-

Can I buy INSITE products through a local agent or distributor?

Yes. If your agent or distributor is willing to purchase and resell our case sealers to you, they are free to do so.

-

Why is INSITE so open with its information?

We want to respect our customers’ time. Operating with openness, transparency and accessibility is the best way to do that. It’s also a simple way for our customers to benefit from our resources so we can spend more of our time investing in the development of even better products at better prices for you.

-

Does INSITE customize its products?

NSITE Packaging Automation’s price points are made possible by our dedication to utilizing standardized parts, components and manufacturing processes. If you need a unique packaging solution, we, as a trailblazing case sealer machine manufacturer (referred to in some parts of the country as a carton sealer machine manufacturer), are pleased to explore the development of a custom case sealer to match your business’ expectations. Our stated price points and lead times, however, may no longer apply.

-

What is the lead-time for an INSITE product?

INSITE Packaging Automation makes every effort to achieve market-acceptable lead times on all our product deliveries. We anticipate 6- to 8-week lead times, depending on the product configuration requested. In many cases, these machines—standard or standard-with-options models—will be stocked and ready to ship in as little as 3 to 4 weeks.

-

What are the possible operating configurations for the sealers?

Four case sealer configurations are available:

- Left-hand glue

- Left-hand tape

- Right-hand glue

- Right-hand tape

Depending on the model, our case sealers are rated to operate up to 30 cases per minute.

-

What are the physical dimensions of the sealers?

6.9’ long x 2.7’ wide (82.8” x 32.4”).

-

What case size ranges can INSITE’s carton sealers run?

Minimum: 8.0” (L) x 6.0” (W) x 5.0” (D)

Maximum: 22.0” (L) x 16.0” (W) x 16.0” (D) -

How many change points require adjustment during case sealer changeovers?

INSITE’s case sealers require 8 points of change totaling 2 to 4 minutes per changeover..

-

What are the power requirements of INSITE’s box sealing machines?

480V 3Ø, 60 HZ.

-

What are the air requirements for INSITE’s automatic case sealer machines?

70 PSI.

-

What makes INSITE’s case sealer different from competing products?

INSITE Packaging Automation’s case sealers are unique in the number of features and amount of functionality that they offer at this price point. Other packaging sealing machine suppliers might be able to include major flap containment, HMI controls, spring-loaded side belts and full-length guard doors with their packing sealing machines, but the cost of these products may well exceed the cost of INSITE’s products.

-

Why are case sealers sometimes referred to as carton sealers?

As mentioned earlier, case sealers are often referred to by many different names. For seasoned professionals in the secondary packaging industry, confusion may occur over use of the term “carton” and related terms such as carton sealers, carton sealing machine, carton box sealer, carton sealing equipment, carton sealing tape machine, carton top sealer, heavy-duty carton sealer and automatic carton sealer machine.

Although “boxes” and “cartons” are sometimes used interchangeably, the reality is that these two products feature key differences. Boxes are constructed from corrugated fiberboard, also widely referred to as corrugated cardboard or corrugated board. Corrugated fiberboard is thicker than the material used to make cartons. Corrugated fiberboard comprises multiple layers of paper along with a fluted interior layer. Cartons are constructed from paperboard, which is generally a single-ply construction and thinner than cardboard but thicker than paper.

One could consider boxes to be made from rugged materials that could be safely shipped whereas cartons are made to contain, for example, lightweight products such as cereal and trash bags but could not withstand the rigors of shipping.

Carton sealer machine manufacturers are actually erecting paperboard carton material. Thus, INSITE Packaging Automation’s case sealers are technically not carton sealers or carton sealing machines. INSITE’s box sealers and box tapers (other common names for case sealers) seal cases made from corrugated material.