Straight, Forward, Sealing.

Case Sealers

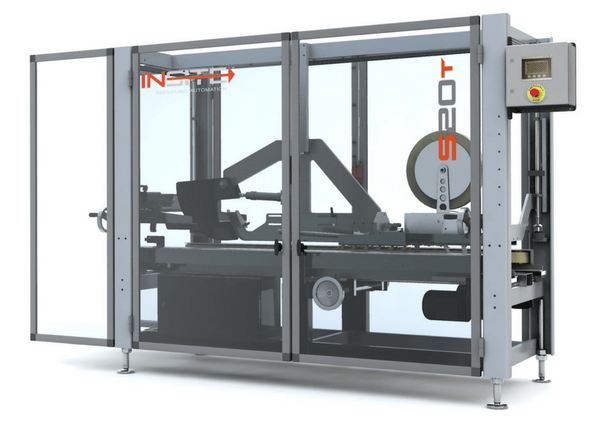

INSITE case sealers combine clean, minimalist design with powerful functionality. Every machine is engineered to deliver reliable, consistent sealing performance across a wide range of case sizes and throughput requirements – without requiring costly upgrades.

Safe, dependable and effortless to maintain, our case sealers help you elevate packaging quality, reduce downtime and have the lowest total cost of ownership in the market.

Why Choose INSITE Case Sealers

A sealed case is the outcome – how you achieve it is the differentiator. INSITE case sealers are designed to answer the most important operational questions:

- Will it seal securely and consistently?

- Will it run reliably without jams or unplanned stops?

- Will it handle cases firmly without damaging product?

- Will it keep operators safe and free up time to add value elsewhere?

With INSITE, the answer is always yes. Our sealers deliver predictable performance, intuitive operation and long-term dependability.

Key Features

Parameterized Recipe Generation

Input case dimensions, make a few quick adjustments and start running. New recipes can be created in minutes.

Spring-Loaded Side Belts

Provide controlled grip across inconsistent width tolerances, ensuring smooth conveyance without crushing or scuffing the case.

Intuitive Touchscreen Controls

A modern HMI comes standard, putting easy recipe creation and system control right at your operators’ fingertips.

Full-Length Guard Doors

Safety-first design. Operators are protected while the machine runs yet have complete access for replenishing tape and routine maintenance when the machine is stopped.

Tilt-Accessible Tape Head

The tape head tilts forward for easy access or quick removal, minimizing service time and simplifying tape roll changes.

Standard Major Flap Control

Major flaps are automatically controlled to eliminate jams, protect product and improve uptime, without added cost.

Portable & Configurable

Optional locking casters enable simple relocation. Machines can convert between left-hand and right-hand operation with ease.

Bottom Tape Option

Optional bottom tape sealing for hand-pack operations or combined glue/tape applications.

Options

Most features that other manufacturers upcharge for are standard on our machines. Additional options allow you to tailor the system to your operation.

Included as Standard

- Left- or right-hand orientation

- Touchscreen controls

- Major flap control

- Infeed metering gate

- CATCAT 3 Safety (glue machines; optional on tape)

Available Options/Customizations

- Caster portability

- Low tape/glue alerts with stack light

- Spare parts kit

- 3” tape head (Dekka option also available)

- Bottom tape (3” Dekka option also available)

- Dust cover

- Infeed metering gate

- Quick access overhead

- Open flap detection

- Swivel HMI

- Alternate discharge height

- Case kits to extend size range

- Glue auto fill

- Hand load station

- Alternate tape heads

- Remote connection devices

- Festo pneumatics

Specifications

If you need additional information, contact us.

| S20T | S20G | S20GT | S30T | S30G | S30GT | |

|---|---|---|---|---|---|---|

| Max. Speed (cpm) | 20 | 20 | 20 | Up to 30 | Up to 30 | Up to 30 |

| Min. Case Size | 6” (L) x 5.25” (W) x 5” (H) Options to accommodate 3” (W) and 2.5” (H) | |||||

| Max. Case Size | 24” (L) x 17” (W) x 17” (H) Options to accommodate 18” (W) and 20” (H) | |||||

| Min. Flap Length | 2.5" | |||||

| Max. Flap Length | 8" | |||||

| Case Types | Regular Slotted Cases (RSC), pass through for Half-Slotted Containers (HSC) | |||||

| Infeed / Discharge Height | 27” Nominal (20” to 31” adjustable) Other options available | 22" to 32" | ||||

| Machine Footprint | 6.9’ x 2.7’ | |||||

| Frame to Floor Clearance | 5” to 14” (adjustable) | |||||

| Frame | Formed sheet metal and bar stock | |||||

| Cleaning - Structure | All-purpose, spray-on cleaner, 5-10 pH (non-electrical only) | |||||

| Finish | Powder coat | |||||

| Environment | Machine is intended to operate in dry, non-wash down, low-humidity environments | |||||

| Max. Ambient Temp. | 100° F | |||||

| Min. Ambient Temp. | 35° F | |||||

| Max. Humidty | 75% | |||||

| Changeover Points | 8 | |||||

| Changeover Types | Tool-less | |||||

| Changeover Time (approx) | ~ 2.5 to 5 minutes | |||||

| Top Tape Width | 2" or 3" | N/A | 2" or 3" | 2" or 3" | N/A | 2" or 3" |

| Glue System | N/A | Nordson Flex | Nordson Flex | N/A | Nordson Flex | Nordson Flex |

| Guarding | Lexan doors with electronic switches | |||||

| Cleaning - Lexan | Clean with a soft, damp cloth. Abrasive pads should not be used. | |||||

| Lubrication | Non-food grade, lifetime lubrication, sealed-for-life gearboxes | |||||

| NEMA Rating | 12 | |||||

| Electrical Components | Allen Bradley, Powerflex VFDs | |||||

| Power Requirements | 480 3Ø / 60 HZ | |||||

| Electrical Drops | 1 | 2 | 2 | 1 | 2 | 2 |

| Main Electrical Drop | 30 AMP rated disconnect; fused for 15 AMP | |||||

| Glue Electrical Drop | N/A | 30 AMP; fused @ 15 AMP | 30 AMP; fused @ 15 AMP | N/A | 30 AMP; fused @ 15 AMP | 30 AMP; fused @ 15 AMP |

| Est. AMP Loads | 1.7 | 6.7 | 6.7 | 1.7 | 6.7 | 6.7 |

| Air | 3.5 SCFM @ 70 psi | 4.25 SCFM @ 70 psi | 4.25 SCFM @ 70 psi | 3.5 SCFM @ 70 psi | 4.25 SCFM @ 70 psi | 4.25 SCFM @ 70 psi |

| Machine Efficiency | Case and/or product samples are required to validate size range and guarantee speed rates. |

Innovations That Set INSITE Apart

We aim to continuously build on new ideas that make our packaging equipment even more effective. INSITE case sealers use a range of inventive technologies, systems and designs to increase the speed, quality and reliability of your sealing operations, all while respecting your budget.

-

Advanced Flap Containment

Major flaps are consistently controlled – eliminating a common cause of jams and damaged cases typically seen in competitive systems.

-

One Machine, Broad Capability

Run from 1 to 30 cases per minute in a wide range of case sizes on one machine. This reduces equipment footprint and capital cost.

-

Designed to Save

A symmetrical, modular sealing platform reduces manufacturing complexity and ensures lower pricing without compromising on performance.

Innovation With Intent

Every INSITE solution is engineered to help you package more efficiently, safely, and cost-effectively. As your production evolves, we can help you develop your automation. It’s built on purposeful innovation, unmatched accessibility and a commitment to long-term value. Couple that with unrivaled customer service, empowering your business with the tools it needs to take your packaging automation to the next level.

Resources

Floor Plans

-

Floor Plan for Sealer / Glue.pdf

This 1-page pdf provides you with a clear understanding of the space that our glue case sealer will occupy on your plant floor.

-

Floor Plan for Sealer / Glue.dwg

This dwg file provides you with a clear understanding of the space that our glue case sealer will occupy on your plant floor.

-

Floor Plan for Sealer / Tape.pdf

This 1-page pdf provides you with a clear understanding of the space that our tape case sealer will occupy on your plant floor.

-

Floor Plan for Sealer / Tape.dwg

This .dwg file provides you with a clear understanding of the space that our tape case sealer will occupy on your plant floor.

-

Definition: Left Hand Machine.pdf

While this pdf describing a 'left hand' machine uses an erector to demonstrate, the 'hand' of the machine is still determined the same way.

-

Definition: Right Hand Machine.pdf

While this pdf describing a 'right hand' machine uses an erector to demonstrate, the 'hand' of the machine is still determined the same way.

Videos

See our case sealer in action.

-

Case Sealer 3D Video

Explore the innovations, features and specs of our Case Sealer.

-

S20T Tape Seal Animation

Check out this animation depicting our S20T tape top sealing machine as it accepts incoming product, controls the major flaps and seals the case tops!

Discover Other INSITE Solutions

Looking to pair your sealer with a high-performance case erector? We deliver fast, reliable, high-performance case erectors – perfectly matched to our sealer offering.

FAQ: Case Sealers

-

What is a case sealer?

A case sealer is a machine that closes and seals corrugated cases. They are available in semi-automated and fully automated varieties and expedite the case sealing process in production lines.

-

Are INSITE’s case sealers fully automatic?

Yes, INSITE’s case sealers qualify as high speed, fully automatic sealers.

-

How do I determine “machine hand”?

INSITE determines machine hand by standing on the operator/HMI side of the box erector machine and observing the direction the cases travel. If the case blank moves from right to left as it’s erected and sealed, you are looking at a left-hand machine. If the case blank moves from left to right as it’s erected and sealed, you are looking at a right-hand machine. (See diagram.)

-

Does 'case hand' matter with INSITE’s case sealers?

No, our sealers can run left- and right-hand cases on the same machine.

-

What type of hot-melt glue does INSITE recommend?

INSITE recommends HB Fuller Advantra PHC 9256 or Henkel Technomelt Supra 106M.

-

How much do INSITE case sealers cost?

Go to our Get a Quote page to walk through the configuration process and get a budgetary quote for a case sealer.

-

Can I buy INSITE products through a local agent or distributor?

Yes. If your agent or distributor is willing to purchase and resell our case sealers to you, they are free to do so.

-

Why is INSITE so open with its information?

Operating with openness, transparency and accessibility is an easy way to respect your time. It’s also an easy way to get the most out of our resources so we can invest our money in creating better products at better prices for you.

-

Does INSITE customize its products?

Yes—while standardized components help control cost and lead time, INSITE can develop custom solutions when needed.

-

What is the lead-time for an INSITE product?

INSITE strives to achieve market-acceptable lead times on all product deliveries. To start, we anticipate 8- to 16-week lead times, depending on the product configuration requested.