Why Active Case Squaring Is Important

Published June 24, 2019

In a world filled with flashy advertisements and graphics, appearance is everything. Case erectors increase throughput and ensure that a product’s primary and secondary packaging look good, setting your products up for success from the start.

These machines have significant performance advantages over their human counterparts – in fact, case erectors can form cartons both faster and more accurately than human operators. And unlike people, they don’t get tired towards the end of their shift! Using a case erector to improve productivity and reduce labor costs also ensures that the quality of your cartons is top-notch every time. The right case erector consistently forms square cases for the duration of its operating life.

The Role of Case Erectors

So, why does every case need to be erected in precisely the right manner? To begin with, it’s crucial for each and every case to be perfectly square as cases pack, stack and palletize better when they’re erected with 90-degree corners. A case erecting machine forms square corners that provide a stable base and strong support for the cartons above it. These strong, square corners create a foundation for weight distribution that helps prevent pallet collapse – an incident that can seriously impact the speed of your production process and the cost.

Good case erectors have continuous control over cases as they are forming. This continuous control helps avoid jams, ultimately minimizing downtime and increasing your operating efficiency.

When cases aren’t precisely aligned, your operations are directly impacted. We even have the numbers to back this statement up. When building a pallet load, 30 percent of stacking strength is lost when case sides aren’t vertically aligned! Square cases are the building blocks to better loads, reduced product damage and increased efficiency. The bottom line: the right secondary packaging machines can help you erect and seal cases faster, better and cheaper.

Active Case Squaring with INSITE

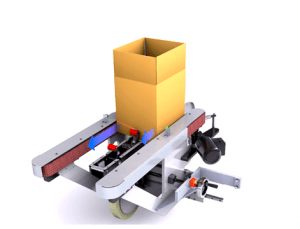

INSITE’s case erectors deliver consistently square cases every time, thanks to our innovative use of active case squaring technology. How does it work? Our design is simple, straightforward and intelligent. Photo eyes ensure all cases are squared before they are sealed. If a case is skewed, the independently driven side belts respond with a microburst of speed to adjust the case, making it square every time.

To see this innovative technology in action, check out our video below. Watch closely, and you’ll notice the instantaneous adjustments made by the independent side belts as the cases pass the photo eyes.

Your case erector should produce more than just a bottom-sealed case; it should create reliably square cases at a consistent speed that simplifies and streamlines your production process. Your secondary packaging equipment should also be easy and safe to operate. In other words, you should have a case erector you can trust. INSITE’s case forming machines have been designed from the ground up with features designed to inspire that trust. This advanced, yet simple machine, combines our simplified SCARA opening and transfer sequence with an elegant active squaring feature to process up to 30 perfectly square cases per minute. With INSITE, you get it all – speed, streamlined design, efficiency and trustworthiness.

If you have any questions about case squaring that we haven’t answered, give us a call, shoot us an email, or drop us a line. We’re here to help with a whole range of packaging inspiration, innovative solutions, and above all – insight!