Modular Automation: The low-risk, high-reward key to your secondary packaging evolution

Published April 4, 2023

Is your company’s secondary packaging operation mostly manual? If it is, then there is a strong chance that labor availability, product throughput, or employee safety are forcing you to consider some level of automation.

Manual secondary packaging challenges:

Labor Availability

Product Throughput

Employee Safety

The problem is that if you are not ready for it, automation presents its own risks. It can add unwanted complexity, limit your flexibility and responsiveness to customer needs, and be challenging to see a sufficient return on your investment.

Fully integrated, fully automated secondary packaging challenges:

More Complexity

Less Flexibility

Ability to Achieve ROI

So, what should you do if you need to move past manual operations, but are not ready for fully integrated automation? There is a middle ground that may be worth considering: Modular Automation.

Modular Automation enables the benefits of auotmation, without some of the risk

Modular automation offers a lower-risk, high-reward path to packaging automation. This article will explore the challenges and drawbacks of fully manual, or fully automated secondary packaging, and will outline the details and benefits of modular automation.

Manual secondary packaging processes present challenges

Throughput

Manual packaging is a labor-intensive process that can limit throughput and slow down production lines. It requires people to physically erect cases, pick up product, fill boxes or bags with those products, seal the packages, label them and then move them onto conveyor belts or into storage areas.

This manual work takes time and energy as each item must be handled multiple times before it is ready for shipping. In addition to taking more time than automated processes, manual packaging also increases the chances of human error which hampers throughput.

Labor Availability

Perhaps the most pressing challenge associated with manual packaging processes is labor. Manual processes require a large number of workers to complete. In today’s labor market, where competition for labor is high and employee loyalty is low, this presents a problem. The challenge of obtaining adequate labor can lead to inconsistent productivity, increased costs, or both.

While workforce availability may be a problem regardless of whether or not you have automated packaging lines, the problem is amplified if you rely exclusively on manual labor to package and ship your goods.

Safety

Manual packaging operations present a unique challenge to safety. Since they require workers to move products, tools and materials with their hands and bodies, it puts your employees at risk of physical injuries, such as cuts, strains, fractures and repetitive stress injuries.

Since employers are obligated by law to provide safe working conditions for their employees, they are incentivized to remove safety risks from their businesses wherever possible. While this may be costly and resource intensive, it is even worse if they experience a recordable workplace injury. Manual operations increase the probability that such injuries occur.

Opportunity Cost

All of the challenges listed above combine to limit the amount of product a food or beverage producer can ship to its customers. To the extent that customer demand is higher than what you can supply, manual operations ultimately mean that you are missing out on an opportunity to earn more revenue – revenue that you could earn if you implemented more automation in your packaging lines.

Fully automated secondary packaging also comes with risk

Return on initial investment

Fully integrated packaging automation usually incorporates multiple functions in a single machine. For example, a fully automated case packer may erect the case, pack the case and seal the case before sending it down the line. Multiple functions in a single machine can come at a cost. It is not uncommon for these types of case packers to cost $500,000, or more.

If you choose to spend this type of money on automation equipment, you need to be certain that the benefits of automating – i.e., revenue or profit – far outweigh the cost of acquiring, installing, operating and maintaining that equipment. In fact, many producers require that their automation equipment pays for itself in two to three years’ time. If you are a smaller company still growing your customer base, these types of justifications might be a challenge.

Lack of flexibility

As noted above, fully automated packaging solutions are designed to complete specific tasks, often multiple tasks in the same machine. This forces machine manufacturers to make design decisions based on the product that the CPG manufacturer intends to run.

If consumer sentiment changes, or if retailers demand a different size or shape of package, you may be unable to accommodate those changes on equipment that was designed for something else. Or, if you do try to accommodate it, expensive machine modifications are often required to make it possible.

Increased complexity

High-end packaging automation requires operator training and regular maintenance. Often, electrical and mechanical skill sets are required. In today’s workforce environment, these skills are not always easy to find. And if you find them, they are often hard to keep.

The necessary technical needs are magnified with each additional function a machine executes. In other words, a case packer that also erects and seals the case is more complex to operate and maintain than a case packer that simply packs a case, leaving erecting and sealing to be done manually or via separate machines.

Space constraints

Finally, this higher level of automation complexity has another impact that is sometimes overlooked – space. The ‘footprint’ of a manual station will usually be smaller than whatever can be designed to automate that particular process. And if equipment is designed to perform multiple processes, they will be even larger. Often, the footprint required of the machine is what it is and cannot be re-shaped to fit into a specific loation if it is too large.

‘Modular’ automation strikes a balance

What if you could achieve the best of both worlds? To get the benefits of automation while ensuring project ROI, maintaining flexibility and reducing complexity, consider modular automation.

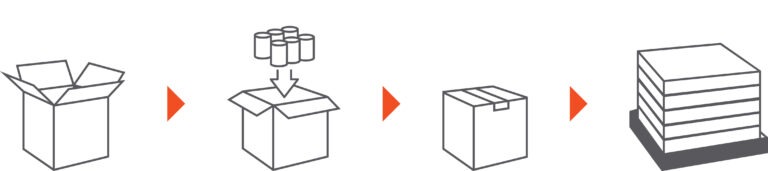

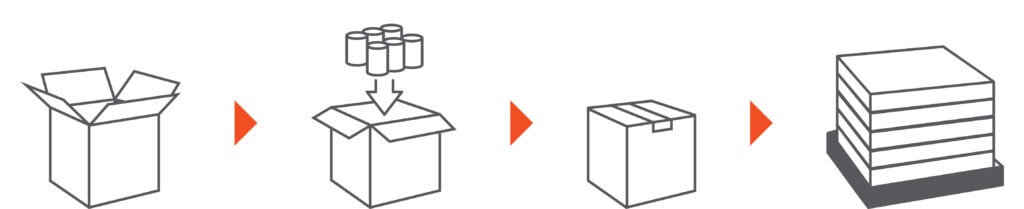

Modular automation breaks the key functions of secondary packaging operations in individual parts or modules. At a high level, these modules are:

- Case erecting

- Case loading

- Case sealing

- Palletizing

The key to modular automation is recognizing that you have a choice with each of these modules. You can either maintain manual packaging processes, or you can automate them. And when you do decide to automate, you do not have to do it all at once. You can choose your biggest pain point or bottle neck and invest in automation there, first.

Having a choice about which modules to automation helps ensure that you are not risking too heavy of an investment. It also allows you to maintain floorplan flexibility since these modules can be configured however and wherever you like, with conveyors easily linking them.

And finally, if you do automate a particular module, it will be as simple and straightforward as it can be since it is only performing one task.

Are you ready for automation but unsure how to proceed? Consider a phased modular approach. With this approach, you choose the pace at which you automate while gaining the benefits and limiting your risk.

Let’s chat about how Modular Automation can help you reach your production goals.