Feature Spotlight: Opposing-Cup/Positive Case Open

Published March 29, 2019

A case erector’s first task is to open a case. Many erectors struggle to account for glue overspray along the manufacturer’s joint, or the dreaded ‘L-shaped’ case. On both accounts, INSITE’s opposing-cup effector takes care of business. Here are some commonly asked questions and key information on our high-quality case erector.

What is Positive Opening?

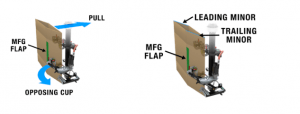

Many case openers rely upon force or leverage to open knockdown cases. Typically, vacuum cups are placed on the major panel of the case, and leverage is placed on the minor panel (labeled LEADING MINOR in second diagram below). Leverage is commonly placed on the minor panel by pulling the blank into a rail, which forces the case to open as it is pulled into the fixed rail.

INSITE uses positive opening or opposing-cup. Following our method, an additional vacuum cup on a pivoting arm is applied to the back side minor panel. The rotating action of the arm positively opens the case.

Why Positive Opening?

Square cases (which are equal in length and width) can be the most problematic case forms to open consistently. When opened with a fixed rail, the geometry of a square sided case concentrates the force back into the case itself, causing an “L” shape or inverted open in which the blank is forced into the fixed rail.

What About Glue Overspray?

When a case is unglued and not connected, it is classified as a wraparound case. Glue is applied to the manufacturing flap (MFG flap) to form a wraparound case into a knockdown case. It is common for overspray to occur during the application of glue to the MFG flap. This glue overspray can effectively connect the major and minor panels together, which can significantly hinder the ability of the case to open – if not make it impossible to open altogether.

A positive opener (opposing-cup) places a cup on the minor panel with the main cups pulling on the major panel. This significantly improves the vacuum cup’s ability to overcome the overspray of glue that has bonded the major and minor panels together. Overall, positive opening provides a significantly greater efficiency in opening cases regardless of size or shape and glue overspray that can prevent cases from opening properly.

Forming a Square Case

Previously, when we mentioned “square cases,” we were referring to the fact that the case length and width were the same dimension. Here, we are describing how “square” the major panel is in relationship to the minor panel. The opposing-cup arm of INSITE’s case erector opens a case so that the minor panel is at a right angle to the major panel, creating a case that has square angles.

The first image below shows the case being opened with an opposing-cup. When opposing-cup is not used, a fixed rail sits in front of the leading minor, and the blank is pulled into it. This causes the case to open, inverting to an “L” shape, or directs the force back through the leading minor panel into the major panel, then to the MFG flap. Glue overspray could cause the major and minor panels to connect.

Features & Benefits of Opposing-Cup/Positive Open

– Opens cases that are dimensionally square.

– Opens cases that are glued shut due to glue overspray on the MFG flap.

– Prevents “L” shaped cases or cases that invert upon opening due to forcing the leading minor panel.

– Without positive open, blanks are pulled by the major panel into a rail (leading minor hits the rail), causing the blank to open. A positive open pulls on the trailing minor, which is closer to the MFG flap and the glue overspray that connects the major and trailing minor panels.

– Opens a case so the major and minor panels are at 90° (right angles) to each other, creating a square case.

– Opposing cup places the opposing force right at the point of glue overspray or weakness in the corrugated (“L” shaped or inverted at the MFG flap and trailing minor panel) instead of driving the force through the leading minor, then to the major, then to the MFG flap.

Ensure Excellence with INSITE

At INSITE, we’re passionate about delivering high-quality, cost-effective packaging solutions to producers on all levels of the CPG industry. Our experts have years of experience building streamlined equipment for the secondary packaging industry and are pleased to offer technical support around the clock. Contact INSITE today for more information on our innovative packaging case sealers and case erectors.