Packaging automation is paramount in the production and distribution of goods, yet many businesses still rely on manual labor throughout the process. Enter packaging automation – a smart way to streamline operations, maximize throughput, improve safety, cut costs, and enhance quality control. In this article, we will define secondary packaging and focus on ways it can benefit your business. Get ready to take the next step and enhance your processes to take your business to the next level!

What is ‘Secondary Packaging Automation’?

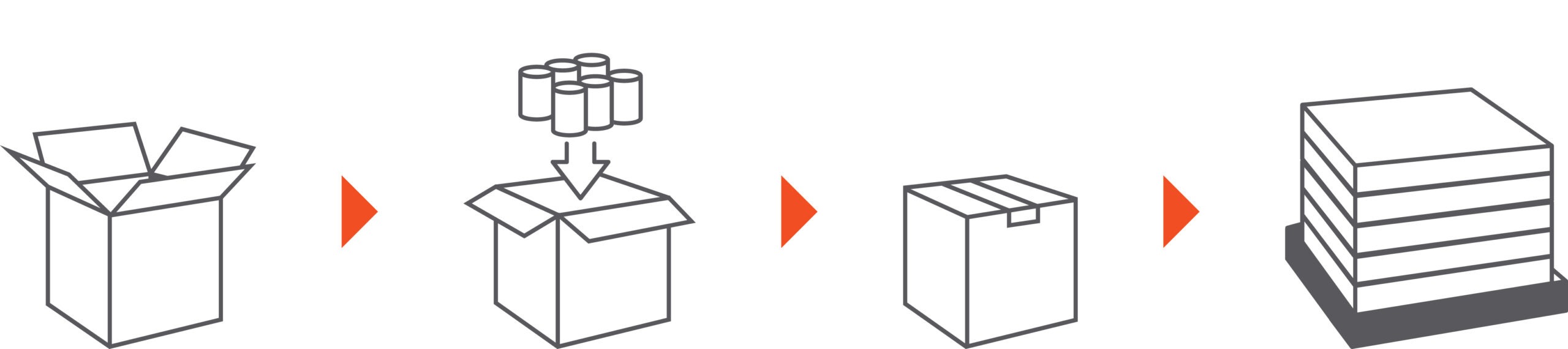

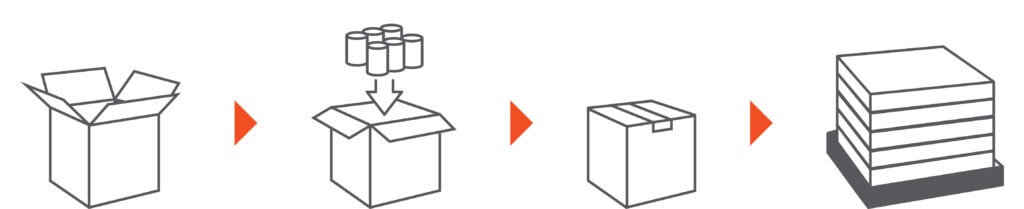

Secondary packaging automation refers to the use of machines and technology for packaging products that have already been packaged in their primary container. Putting soda into a bottle or chips into a bag are examples of ‘primary’ packaging. However, when those bottles or bags are combined with other bottles or bags to create a multipack, it is considered ‘secondary’ packaging.

A good rule of thumb to understand whether a process is ‘primary’ or ‘secondary’:

If it handles or touches the actual product being consumed, it is ‘primary’ packaging. If not, it is probably ‘secondary’ packaging.

Primary Packaging

Handles or touches the actual product being consumed

Secondary Packaging

Packages products into groups

The purpose of secondary packaging is to group and protect primary packaged products during storage and transportation. by containing the primary packages in boxes, cartons, trays, or shrink wrap, food and beverage manufacturers can protect their products while also making it easier for retailers and end users to handle and transport them. Usually, secondary packaging is customized to fit the specific needs of the products, including shape, size, and design.

Since secondary packaging provides additional space for labeling, branding and other information, it provides marketing benefits, as well.

What are Some Examples of Secondary Packaging Automation?

Automation for secondary packaging typically includes processes such as conveying, labeling, and collating the primary container before prepping, loading, and sealing the secondary container. For food products, that secondary container is usually a paperboard carton or corrugate case. For beverage products, the secondary container is often paperboard or shrink wrap.

Below you will find brief explanations for the most common secondary packaging automation technologies. In a subsequent post, we will explore each of these technologies in greater detail.

Conveyors

Conveyors are a common element of packaging automation used to move products from one point to another in the packaging process. Conveyors are used up and down the entire packaging line and are essential for both primary and secondary processes.

Labelers

A machine designed to apply labels to products during the packaging process. Product labelers come in a wide variety of designs and can be customized to fit the specific needs of different products and packaging formats. Product labelers typically use a conveyor belt or other type of feeding mechanism to move products into position, where a label is then applied. The label may contain important information such as the product name, ingredients, expiration date, and bar code.

Collators

A machine or mechanism used in packaging automation that is designed to sort and group products into specific configurations. Collators typically use conveyor belts or other forms of feeding mechanisms to transport products from the input to the output locations. The machine is programmed to arrange products in specific configurations, which can be customized to fit the size, shape, and other characteristics of the products being sorted. Some of the most common applications of product collators include grouping products into predetermined quantities, creating multiple packs, and organizing products for display or shelving.

Erectors

A machine designed to automatically form and erect cardboard or corrugated boxes for packaging of products. Usually, erectors will also seal the bottom flaps of the case to prepare it for loading. The case erector works by feeding flat box blanks, usually regular slotted cases (aka RSCs) from a magazine or hopper and then folds and seals them into a ready-to-use box. Erectors can be customized to accommodate a variety of box sizes and styles depending on the product being packaged.

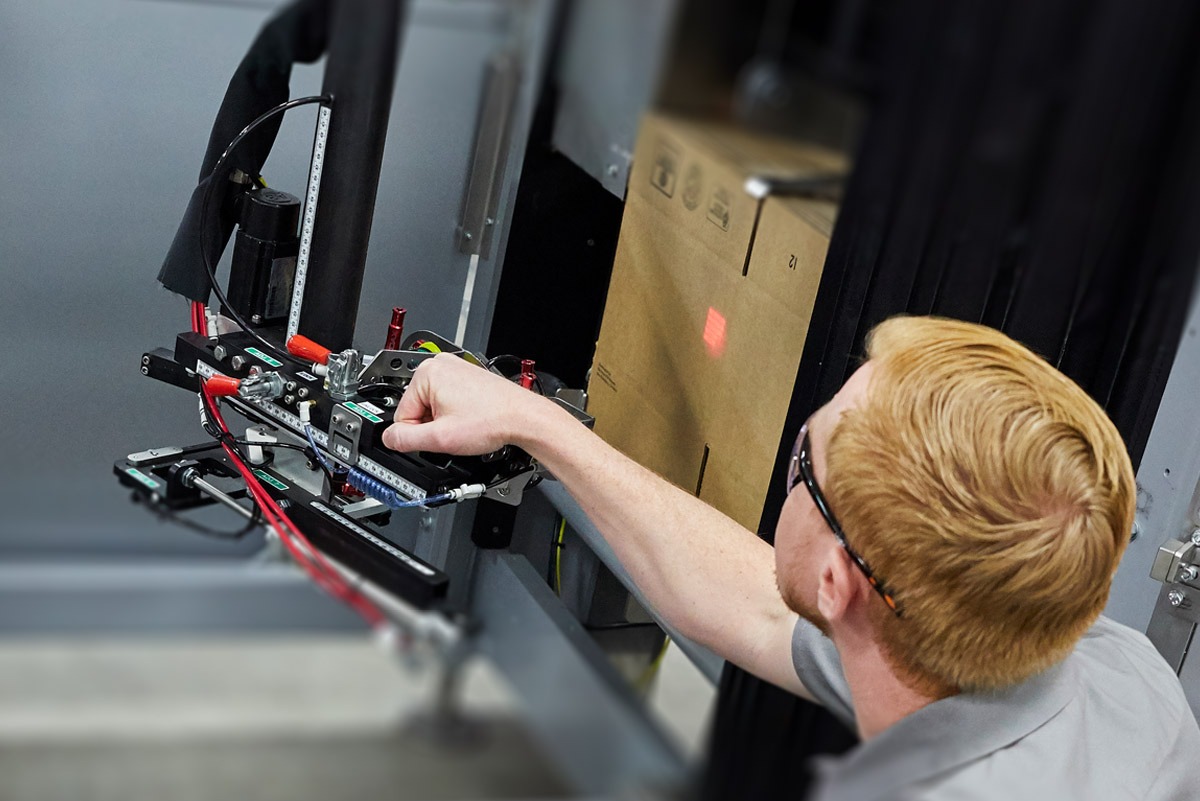

Loaders

A machine designed to load products into pre-formed or wraparound boxes or cases. They typically use a conveyor belt or other feeding mechanism to move products from their source to a staging area where another mechanism places the products into the case envelope. The machine can be customized to handle a variety of product sizes, shapes, and packaging formats, including bottles, cans, bags, boxes and more.

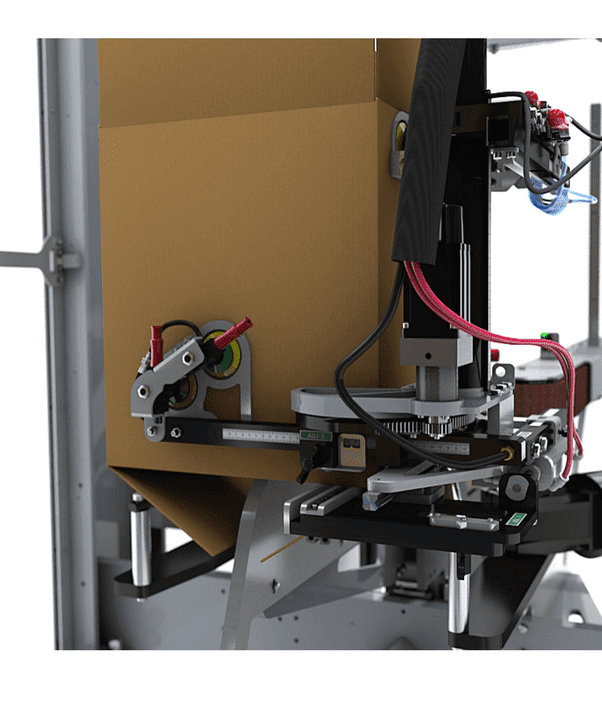

Sealers

A machine designed to automatically seal pre-formed boxes or cases once they are loaded with products. Case sealers typically work by applying tape, glue, or other sealant materials to the top or bottom of the box. The machine can be customized to handle a variety of box sizes and styles, and can also be programmed to automatically adjust to different box dimensions.

What are the Benefits of Implementing Packaging Automation?

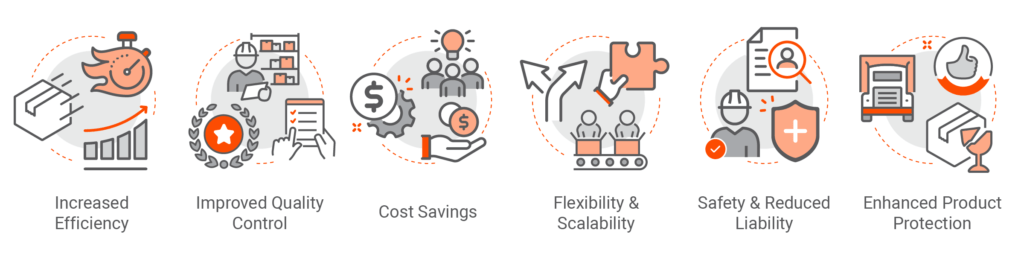

Whether a company is packaging food, beverages, or any other consumer packaged goods, there are several benefits they can gain by implementing packaging automation. They include:

- Increased efficiency: Packaging automation can help businesses produce and package products more quickly and efficiently, reducing production time and increasing output.

- Improved quality control: Automation reduces the risk of human error, which can lead to inconsistencies in product quality. With automated packaging processes, businesses can ensure that each product is packaged the same way, every time.

- Cost savings: Automation can help reduce labor costs and eliminate the need for manual labor, freeing up employees for more specialized tasks.

- Flexibility and scalability: Packaging automation systems can be customized to fit a business’s specific needs and can be scaled up or down as demand changes.

- Safety and reduced liability: Automated packaging systems can improve workplace safety by reducing the risk of accidents and injuries, which can result in reduced liability and workers’ compensation costs.

- Enhanced product protection: Automated packaging systems can provide additional protection to products during transportation and storage, reducing product damage and waste.

Conclusion

Automating your packaging process can work wonders for your business. It streamlines tasks, ensures top-quality products, cuts down on labor expenses, offers versatility to manage demand fluctuations, and safeguards your goods against damage during shipping or warehousing. It is no wonder an increasing number of companies are adopting automated packing systems. Whether you aim to boost productivity or ensure safety in the workplace, going for an automated packaging solution can indeed be a good bet for your business.