Simple. Reliable. Remarkable.

Case Erectors

Case erectors are simple relative to other packaging equipment. Automatic case erectors convert case blanks into fully erected, bottom-sealed cases. Simple as that.

But if you’ve ever struggled with opening a case, getting a case square or removing a jammed case, you know making a case erector is easy to do but hard to do well. When you step up to an INSITE case erector—also occasionally referred to as a box erector or carton erector—you’ll notice how our work can make your work very easy and very fast.

Key Features of INSITE’s Case Erector

Your case erectors should produce more than just a bottom-sealed case. Cases should be reliably square and come at a reliable speed on a machine that is easy and safe to operate as well as unfailingly automatic. In other words, you should have a case erector you can trust. INSITE Packaging Automation’s box erector machines have been designed from the ground up with features designed to inspire trust.

Automated LxWxD path generation

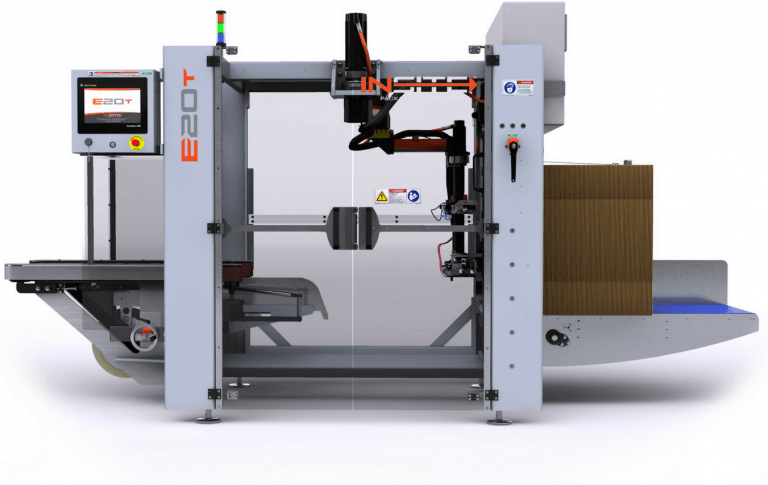

INSITE’s proprietary, advanced motion control software makes it possible to automatically generate a robot’s path using only the outside dimensions of a case. Replace the mechanical mass found in other erectors with INSITE’s single, simple and reliable SCARA robot.

Opposing-cup case opening

A case erector’s first task is to open a case. Many box erector machines struggle to account for glue over-spray along the manufacturer's joint or the dreaded L-shaped case. In both situations, the opposing-cup effector on INSITE Packaging Automation’s case erector takes care of business.

Robotic pick and pass

Smart use of robotics on INSITE’s auto case erectors enables us to get rid of many of the parts and mechanisms in run-of-the-mill case erectors. We replace these parts and mechanisms with a reliable SCARA robot controlled via the Rockwell brand you know and trust. Goodbye to clunking, clattering, knocking, slamming, fiddling, fixing and finessing. Hello, simple!

Safety and ergonomics

We’ve gone out of our way to ensure your operators' safety and health when using INSITE’s case erecting equipment. The magazine infeed is easy to access and limits loading strain. The open-frame structure puts changeover points and sealing modules within easy reach. Governing bodies agree: INSITE Packaging Automation’s case erectors are ANSI/PMMI B155.1, ISO 13849 Category 3, and UL certified.

Active case squaring

INSITE Packaging Automation’s active case squaring feature means that photo eyes ensure all cases are squared before they are sealed. If a case is skewed, our case erectors’ independently driven side belts respond with a microburst of speed to adjust the case, making it square every time.

Durable & sanitary frame design

INSITE's box erector frames are robust, reliable and hygienic. Made from over-engineered tube- and plate-steel and designed with sanitary standards in mind, these frames are built to withstand a 20+ year packaging equipment asset life.

Case Erector Options

INSITE believes in including many of our options as a standard part of our base package for case erectors. Check out the list of options available to you.

| Option | Description | Included in base price |

|---|---|---|

| Left-Hand or Right-Hand Orientation | Choose from either left hand or right hand orientation for any machine | ✔ |

| UL-Listed Electrical Components | UL-approved electrical components are standard | ✔ |

| Category 3 Safety | Redundant circuit for safety functions | ✔ |

| Allen Bradley® Panelview Plus | Panelview Plus 7 is a large, easy-to-use interface | ✔ |

| Hygienic Machine Design | Simple machine design ensures accessibility and easy cleaning | ✔ |

| Electronic Case Squaring | Automatic case squaring and correction with independently driven side belts | ✔ |

| Lubed-for-Life Gearboxes | Simplifies and eliminates maintenance tasks | ✔ |

| HMI Recipe Generation | Create recipes for new case sizes in minutes right on the HMI and retain up to 32 recipes | ✔ |

| Smart Discharge Control | Senses downstream queue and adjusts the erector speed automatically to an average line speed | |

| Low Tape, Low Magazine with Stack Light | Provides audio/visual feedback and low material sensing | |

| 6-Foot Magazine | Additional two feet of magazine capacity | |

| Spare Parts Kit (Tape) | General wear and critical spares kit for tape erectors | |

| Spare Parts Kit (Glue) | General wear and critical spares kit for glue erectors | |

| Polycarbonate Dust Cover | Reduces dust and debris within the machine working area | |

| 3" Tape Head | Replaces standard 2" tape head to enable wider adhesion | |

| Large Case Kit | Expands case size range in length and width to a combined total flat length of 40" | |

| Short Case Kit | Expands capability to run vertically short cases that are narrow (short flaps) | |

| Open Flap Detection | Sensors that detect open or unsealed bottom flaps |

Case Erector Specifications

Below, you’ll see a list of facts and figures about INSITE Packaging Automation’s case erectors. If you’re looking for information that’s not listed here, please contact us. We’ll get you all the information you need to choose the case erecting equipment that works for you.REACH OUT TO US

| E20G | E20T | E30G | E30T | |||||

|---|---|---|---|---|---|---|---|---|

| Max. Speed (cpm) | 20 | 20 | 30 | 30 | ||||

| Min. Case Size | 9" (L) x 5" (W) x 6" (D) Combined miniumum case size. Smaller length or width sizes optional. Contact us for details. | |||||||

| Max. Case Size | 18" (L) x 16" (W) x 16" (D) (L+W must be ≤ 34") Combined maximum case size. Larger length or width sizes optional. Contact us for details. | |||||||

| Min. Flap Length | 2.50" | |||||||

| Max. Flap Length | 8" | |||||||

| Case Types | Regular Slotted Cases (RSC) and Half-Slotted Containers (HSC) | |||||||

| Magazine Length | 4' (48") | 6' (72") | ||||||

| Magazine Capacity | ~130 cases; min ~6.5 min. run time | ~190 cases; min. ~6.5 min. run time | ||||||

| Machine Footprint | 15.15' x 4.66' | 12.90' x 4.66' | 17.15' x 4.66' | 14.90' x 4.66' | ||||

| Magazine Height | 1' 7" x 2' 1" | |||||||

| Discharge Height | 25" to 28" | |||||||

| Frame to Floor Clearance | 3" to corner posts; 5" to center beam | |||||||

| Frame | Tube and plate steel | |||||||

| Cleaning - Structure | All-purpose, spray-on cleaner, 5-10 pH (non-electrical only) | |||||||

| Finish | Powder coat | |||||||

| Environment | Machine is intended to operate in dry, non-wash down, low-humidity environments | |||||||

| Max. Ambient Temp. | 100° F | |||||||

| Min. Ambient Temp. | 35° F | |||||||

| Max. Humidity | 75% | |||||||

| Changeover Points | 12 | 11 | 12 | 11 | ||||

| Changeover Types | ||||||||

| Changeover Time (approx) | ||||||||

| Tape Width | N/A | 2" or 3" | N/A | 2" or 3" | ||||

| Glue System | Nordson ProBlue 7 | N/A | Nordson ProBlue 7 | N/A | ||||

| Vacuum System | Venturi-style | |||||||

| Guarding | Lexan doors with locking switches | |||||||

| Cleaning - Lexan | Clean with a soft, damp cloth. Abrasive pads should not be used. | |||||||

| Lubrication | Non-food grade, lifetime lubrication | |||||||

| NEMA Rating | 12 | |||||||

| Electrical Components | Allen Bradley, Kinetix Servos, Powerflex VFDs | |||||||

| Power Requirements | 480V 3Ø / 60 HZ | |||||||

| Electrical Drops | 2 | 1 | 2 | 1 | ||||

| Main Electrical Drop | 30 AMP rate disconnect; fused for 15 AMP | |||||||

| Glue Electrical Drop | 30 AMP; fused @ 15 AMP | N/A | 30 AMP; fused @ 15 AMP | N/A | ||||

| Est. AMP Loads | 14 | 12 | 14 | 12 | ||||

| Air | 5.3 SCFM @ 70 psi | 5.3 SCFM @ 70 psi | 6 SCFM @ 70 psi | 6 SCFM @ 70 psi | ||||

| Machine Efficiency | Case and/or product samples are required to validate size range and guarantee speed rates. | |||||||

| Options Packages | Smart Discharge Control; Low-Tape and/or Magazine Alert (with stack light); spare parts | |||||||

Case Erector Innovations

INSITE Packaging Automation’s case erectors represent a better alternative to existing box erector machines. These case formers have been reimagined and redesigned from the ground up—untethered by old technologies and incarnations—and emboldened by the potential to infuse an old function with new life and a new goal: making your job easier.

No other case erectors look or perform like ours.

Smooth, on-the-fly robot path generation

The SCARA robot on INSITE’s carton erector is only possible because of innovative software capable of converting a case’s outside dimensions into smooth, clean and efficient motion.

SCARA pick and pass

INSITE Packaging Automation’s advanced motion-control software brings the benefits of robotic functionality to our case erectors: 40 to 60 percent fewer parts, smoother operation, quicker changeovers, less maintenance and dependable performance from the first run, without all the tweaking, adjusting and testing.

Unrivaled simplicity

No other box erector can assemble a case with such clean, quiet and smooth motion. Underpinning it all is the pure, unrivaled simplicity of INSITE’s case erectors. Our machines perform the same function as any other automatic case erector but do it without all the (literal and figurative) noise.

Progress With Purpose

Every single machine and technology INSITE Packaging Automation develops is unified under one goal: increasing the quality and value of your company’s packaging operations. This pursuit drives every aspect of our business, inspiring us to develop new ideas that bring meaningful results to your organization.

Case Erector Resources

Are you interested in learning more about how automatic case erectors function in a real-life production line? Look no further than our floor plan specifications and videos below.

As one of the most experienced packaging machine manufacturers in the business, INSITE Packaging Automation can show you everything you need to know about our incredible packaging solutions—from our case erectors to our case sealers—and the benefits they can bring to your company.

Case Erector Floor Plan Specifications

Customers requiring detailed information about INSITE’s case erectors find value in our collection of case erector floor plan PDFs and DWGs. Our detailed diagrams can provide your team with a clear vision of how our case erector machines will occupy space on your facility’s floor.

-

Floor Plan for Case Erector / Tape / Left Hand.pdf

This 1-page pdf provides you with a clear understanding of the space that our left-hand tape-seal erector will occupy on your plant floor.

-

Floor Plan for Case Erector / Tape / Left Hand.dwg

This .dwg file provides you with a clear understanding of the space that our left-hand tape-seal erector will occupy on your plant floor.

-

Floor Plan for Case Erector / Tape / Right Hand.pdf

This 1-page pdf provides you with a clear understanding of the space that our right-hand tape-seal erector will occupy on your plant floor.

-

Floor Plan for Case Erector / Tape / Right Hand.dwg

This .dwg file provides you with a clear understanding of the space that our right-hand tape-seal erector will occupy on your plant floor.

-

Floor Plan for Case Erector / Glue / Left Hand.pdf

This 1-page diagram provides you with a clear understanding of the space that our left-hand glue-seal erector will occupy on your plant floor.

-

Floor Plan for Case Erector / Glue / Left Hand.dwg

This .dwg file provides you with a clear understanding of the space that our left-hand glue-seal erector will occupy on your plant floor.

-

Floor Plan for Case Erector / Glue / Right Hand.pdf

This 1-page pdf provides you with a clear understanding of the space that our right-hand glue-seal erector will occupy on your plant floor.

-

Floor Plan for Case Erector / Glue / Right Hand.dwg

This .dwg file provides you with a clear understanding of the space that our right-hand glue-seal erector will occupy on your plant floor.

-

Definition: Left Hand Machine / Left Hand Case.pdf

Check out this 1-page tutorial on how to determine whether a particular packaging machine is a 'Left-Hand' machine.

-

Definition: Right Hand Machine / Right Hand Case.pdf

Check out this 1-page tutorial on how to determine whether a particular packaging machine is a 'Right-Hand' machine.

-

INSITE Warranty Statement

This 2-page document outlines INSITE's limited warranty for various aspects of its packaging equipment.

Case Erector Videos

Customers looking for case erector videos benefit considerably by watching INSITE’s case erector machine YouTube videos. These videos highlight our case erectors’ capabilities in active case squaring, SCARA arm movement and other features.

When you can view our detailed and, in some cases, slow-motion carton erector videos, we believe you’ll gain an appreciation for the level of thought that contributed to our design process. The result is automatic case erectors that are built with durability, efficiency and productivity in mind.

3D Video

Experience an overview our INSITE's Case Erector and its stand-out features.

Active Case Squaring

Get perfectly squared cases without stopping production. INSITE case erectors automatically detect skewed corners and use micro-adjustments to correct and ensure all corners are at 90-degree angles.

Changeovers in Under 5 Minutes

INSITE's case erector offers an easy-to-use recipe generation tool with tool-less changeovers. In three simple steps, you can easily set up and run new case sizes in less than five minutes.

Simplified Packaging with SCARA Robot Technology

Our case erector’s SCARA robot technology simplifies everything. Requiring 40-60% fewer parts than a traditional case erector, SCARA enables a leaner, quieter case erector that is easy to learn and easy to operate. Plus, it allows you to run new case sizes in just 2-5 minutes.

Proven & Reliable Case Opening

When a case erector first opens a case, common problems like glue overspray and incorrectly formed cases can slow down production. INSITE's case opening design uses positive case opening (opposing cups) to simplify the process and increase efficiency.

Software Simplifies Machine Operation

INSITE's intuitive HMI brings full case erector control right to the operator's fingertips. Access machine data, generate new recipes and operate the case erector through one simple interface — no advanced training required.

Built for Durability & Safety

The INSITE case erector's open frame design makes components clearly visible and easy to access. Its high durability and accessibility ensure that changeovers and maintenance are simple, safe and efficient.

E20G active case squaring

Look closely and you'll notice the instantaneous adjustments made by the independent side belts as the cases pass the photo eyes.

E20G SCARA arm movement

Watch the smooth motion path of the SCARA robotic arm operating at 20 cases per minute. There's no sound coming from the packaging machine, but even if there were you wouldn't hear much.

E20G at slow speed with no case

Watch INSITE's erector operating at low speeds with no cases. See the entire case erecting process through multiple cycles of 'pick,' 'rack-open,' and 'place'.

E20G erecting at 20 cases per minute

This quick clip demonstrates INSITE's hot-melt glue case erector operating at 20 cases per minute.

E20G 20 cpm dry cycle 1

Click here to view INSITE Packaging Automation's 20 cpm hot-melt glue case erector operating at full speed without cases.

E20G 20 cpm dry cycle 2

This is another perspective demonstrating INSITE's 20 cpm hot-melt glue case erector operating at full speed without cases.

E20 slow speed dry cycle end effector

See the end effector operate in slow motion on INSITE's E20G case erector.

INSITE E20T erector animation

This animation clearly demonstrates why INSITE's E20T tape-seal case erector is so refreshingly simple compared to alternative packaging machines.

INSITE E20G erector animation

This animation clearly demonstrates why INSITE's E20G glue-seal case erector is so refreshingly simple compared to alternative packaging machines.

INSITE E20T Fly-Around

In this wonderful animation you can see the E20T in action from all angles as it erects and tape-seals RSC cases.

Discover INSITE’s Case Sealers

If you’re looking for the ultimate case erector and sealer, INSITE Packaging Automation’s solutions are bound to deliver satisfaction to your team.

Beyond being safe to use, dependable, efficient to operate and simple to maintain, INSITE Packaging Automation’s case sealers work seamlessly with our case erectors in helping businesses improve their packaging operations’ full scope.

Our case sealers can handle a range of case sizes and are equipped to accommodate vast variations in the number of cases that can be sealed each minute.

FAQ: Case Erectors

What is a case erector?

A case erector is a case-forming machine that automatically forms, folds and seals cases from flat, or knock-down, corrugated blank. These efficient machines enable teams to save valuable time from having to construct cases during the product-packing process.

Case erectors are known by many similar names such as case erector machines, automatic case erectors, automatic cardboard box case erectors, fully automatic case erectors, auto case erectors, robotic case erectors, case erectors and packers, case formers, case former machines, base case erectors and case erecting equipment.

Additionally, some refer to these machines as box erectors and related terms, including box erector machines, box erector robots, automatic cardboard box case erectors, automatic box erectors, cardboard box erectors, cardboard box erector machines, carton box erectors and carton box erector machines. These machines are also known by the name carton erectors and related terms such as carton erector machines, automatic carton erectors, automatic carton erector machines, auto carton erectors, carton box erectors and carton box erector machines.

Simply put, case erectors go by numerous names, with some favored in various geographical locations over others. We believe, however, that there is one brand name in the case erector industry that should truly matter to customers seeking out the best case erector: INSITE Packaging Automation.

Are INSITE’s case erectors fully automatic case erectors?

Yes, INSITE’s case erectors are indeed fully automatic case erectors. Our automatic case erectors also utilize SCARA robot technology and may also be referred to as robotic case erectors. Additionally, because of the speed ranges they’re capable of, our auto case erectors may be referred to as high-speed case erectors or high-speed carton erectors.

How do I determine “machine hand”?

INSITE determines machine hand by standing on the operator/HMI side of the box erector machine and observing the direction the cases travel. If the case blank moves from right to left as it’s erected and sealed, you are looking at a left-hand machine. If the case blank moves from left to right as it’s erected and sealed, you are looking at a right-hand machine. (See diagram.)

How do I determine “case hand”?

What case types do INSITE’s case erectors & sealers accommodate?

Regular Slotted Cases (RSCs). INSITE Packaging Automation offers RSC case erectors and case sealers.

What type of hot-melt glue does INSITE recommend?

INSITE recommends HB Fuller Advantra PHC 9256.

How do I configure a case erector, and what options are available?

Visit our Get a Quote page. It will walk you through the simple configuration process.

How much do INSITE case erectors cost?

Go to our Get a Quote page to learn the case erector cost and case erector price for INSITE Packaging Automation’s products. It will walk you through the configuration process and provide you a case erector machine price for your configured packaging machines. Our case erector prices are tailored according to your configuration specifications.

What is the advantage of using a SCARA robot on INSITE’s carton erector?

The SCARA robot enables simple, easy-to-program, repeatable, reliable and smooth case erecting motion. We’ve been doing this for a while, so we know that many other erectors require a certain level of tweaking and finessing to get a line up and running to your satisfaction.

Our SCARA robot eliminates this, enabling extremely straightforward setup and operation. In fact, we tested our box erector on office personnel with no on-machine experience, and they were able to be up and running with a new case in a matter of minutes with minimal fuss.

Can I buy INSITE case erectors through a local agent or distributor?

Yes. If your agent or distributor is willing to purchase and resell our case erector machines to you, they are free to do so.

Why is INSITE so open with its information?

Operating with openness, transparency and accessibility is an easy way to respect your time. It’s also an easy way to get the most out of our resources so we can invest our money in creating better products at better prices for you.

Does INSITE Packaging Automation customize its products?

INSITE’s price points are made possible by our dedication to standardized parts, components and manufacturing processes. If you need something different, we, as a leading case erector manufacturer (sometimes mistakenly referred to as a carton erector machine manufacturer), are happy to help create a custom case erector to suit your business’ needs. Our stated price points and lead times, however, may no longer apply.

What is the lead time for an INSITE case erector?

INSITE strives to achieve market-acceptable lead times on all product deliveries. To start, we anticipate 4- to 6-week lead times, depending on the product configuration requested. Our long-term goal is to have many of these machines in stock and ready to ship within 3 to 4 weeks, assuming the order is for a standard or standard-with-options machine.

What are the possible operating configurations for the box erector?

There are four broad configurations for INSITE’s case erectors:

- Left-hand glue

- Left-hand tape

- Right-hand glue

- Right-hand tape

Currently, all case erectors are rated for 20 or 30 cases per minute and come with the option of either a 4’ or 6’ powered magazine.

What are the physical dimensions of INSITE’s case erectors?

- Tape erector with 4’ magazine: 12.9’ x 4.66’

- Tape erector with 6’ magazine: 14.9’ x 4.66’

- Glue erector with 4’ magazine: 15.15’ x 4.66’

- Glue erector with 6’ magazine: 17.15’ x 4.66’

View footprint diagrams of our glue case erector and tape case erector.

What case size ranges can be run on INSITE’s automatic case erectors?

- Minimum: 9.5” (L) x 5.5” (W) x 5.0” (D)

- Maximum: 18” (L) x 16” (W) x 16” (D)

How many change points require adjustment during case erector changeovers?

INSITE’s tape erectors require 10 points of change totaling between 2½ to 5 minutes.

Our glue erectors require 12 points of change, also totaling between 2½ to 5 minutes.

What are the power requirements of INSITE’s case erector machines?

480V 3Ø, 60 HZ.

What are the air requirements for INSITE’s auto case erector?

90 PSI.

What is the controls system for INSITE’s carton erector machine?

Allen Bradley, Kinetix Servos, Powerflex VFDs.

Is there an HMI on the box erector robot?

Yes

Are there any air cylinders on INSITE’s case erectors?

Yes, there are two Festo air cylinders.

Are there any options for the automatic case erector?

Yes, there are 7 options available on our case erectors:

- Low materials with stack light

- 6’ magazine

- Smart discharge control

- 3” tape

- Spare Parts Kit

- Polycarbonate debris cover

- Operator side disconnect. (This is required by few customers for entry into the machine in jam clearing and removes power to the motor but not the drive. Removing power from the drive lengthens recovery time.) Our standard is a main disconnect that removes all power and is located on the enclosure over the magazine.

What makes INSITE’s case erector different from competing products?

INSITE Packaging Automation’s case erectors offer a number of notable differences compared with competing products. The biggest difference is our machine’s simplicity. By replacing traditional mechanical movement with a SCARA robot, we’re able to drastically reduce the number of components that each machine requires.

With fewer components comes improvements in usability, reliability, maintainability and other areas.

Why are case erectors sometimes referred to as carton erectors?

As stated previously, case erectors are often referenced by a number of different names. For industry professionals with a lot of experience in secondary packaging, the most perplexing names have to do with the use of the term “carton” and related terms such as carton erectors, carton erector machine, carton erector and sealer, carton box erector and carton box erector machine.

Let’s briefly explore the differences between boxes and cartons. Boxes are made from corrugated fiberboard, also known as corrugated cardboard or corrugated board. This material runs thicker than the material used to make cartons, as it comprises multiple layers of paper along with a fluted interior layer. Cartons are made from paperboard, which is usually a thin, single-ply construction and thicker than paper.

In less-technical terms, you could consider boxes to be shipping-friendly whereas cartons are suitable for store-self products such as cereal or plastic wrap.

Technically speaking, carton erector machine manufacturers are actually erecting paperboard carton material. For this reason, INSITE case erectors are technically not carton erector machines. Instead, INSITE box formers (another name for case erectors) form corrugated material into sealed cases.